3D Modeling for Complex Structures: How Testronix Tackles Intricate Geometries for Vendors

Introduction

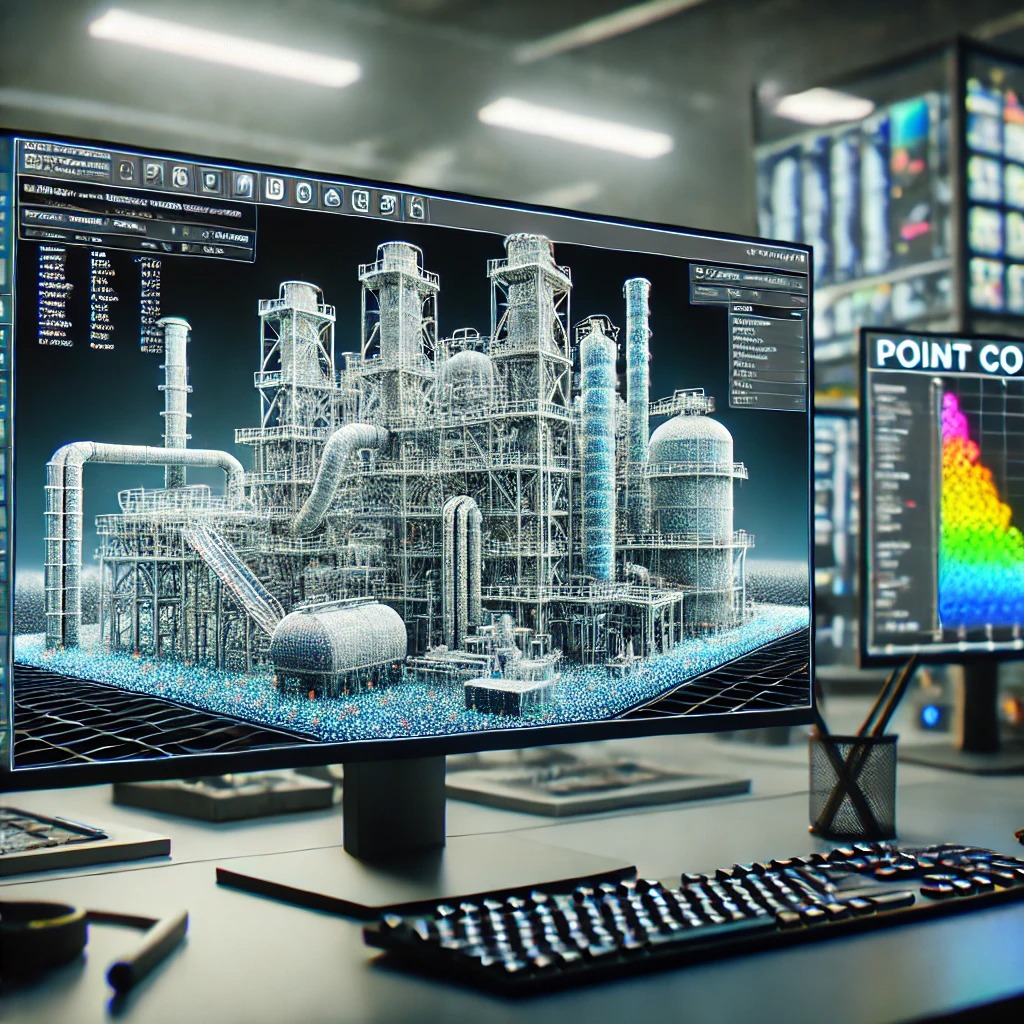

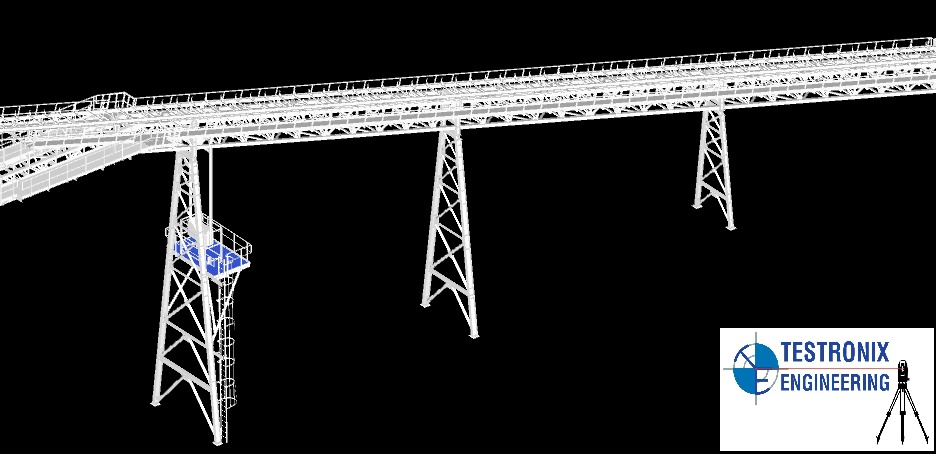

Creating 3D models for complex structures is a feat of engineering that requires both precision and advanced technology. As industries like oil and gas, power plants, and large-scale manufacturing increasingly rely on digital representations for planning and project validation, the demand for accurate, detailed 3D models has surged. However, modeling these intricate geometries—from interwoven piping systems to dense structural frameworks—is challenging. This is where Testronix Engineering shines. Our expertise in converting complex point cloud data into precise 3D models has empowered vendors to visualize and manage their assets like never before.

In this post, we’ll explore the unique challenges in 3D modeling complex structures, how Testronix addresses them, and why our approach makes us the trusted choice for tackling intricate geometries. If you’re ready to see your complex assets modeled in detail, our team is here to bring your vision to life.

The Challenge of Complex Geometries in 3D Modeling

3D modeling for industrial assets involves more than just replicating shapes—it’s about accuracy, readability, and ensuring models are actionable. Complex structures often contain overlapping elements, various surface textures, and extensive piping and ductwork. Converting these details from raw point cloud data into a cohesive 3D model involves several challenges, such as:

- High-Resolution Requirements: The intricacy of complex structures requires high-resolution scans, producing immense amounts of point cloud data.

- Noise in Point Cloud Data: Scanning large structures or active industrial areas introduces noise and incomplete data, complicating the conversion into accurate 3D representations.

- Geometric Complexity: Structures with interwoven or layered geometries, like pipe racks and intricate frameworks, demand careful modeling to ensure clarity and fidelity.

- Rendering Usable Models: Converting dense point cloud data into streamlined models that vendors can use in design applications or presentations is no small feat. Simplifying without losing detail is crucial for usability.

- Software Compatibility and Constraints: Managing large data sets across various software formats while ensuring compatibility with platforms commonly used by vendors.

How Testronix Solves These Challenges

At Testronix Engineering, we understand that each project is unique. Our approach combines industry-leading laser scanning tools, such as the RTC 360, with in-depth expertise in 3D modeling. Here’s how we overcome the hurdles of modeling complex geometries:

- High-Precision Laser Scanning : Using advanced laser scanners, Testronix captures high-density point cloud data that provides a detailed foundation for modeling. This level of precision ensures that even the smallest elements are recorded, resulting in accurate and usable 3D representations.

- Advanced Data Processing Techniques : We employ specialized data processing methods to clean and filter point cloud data, removing noise and filling gaps where scans may have missed details. By refining raw data, we achieve clarity that is critical for accurate 3D modeling.

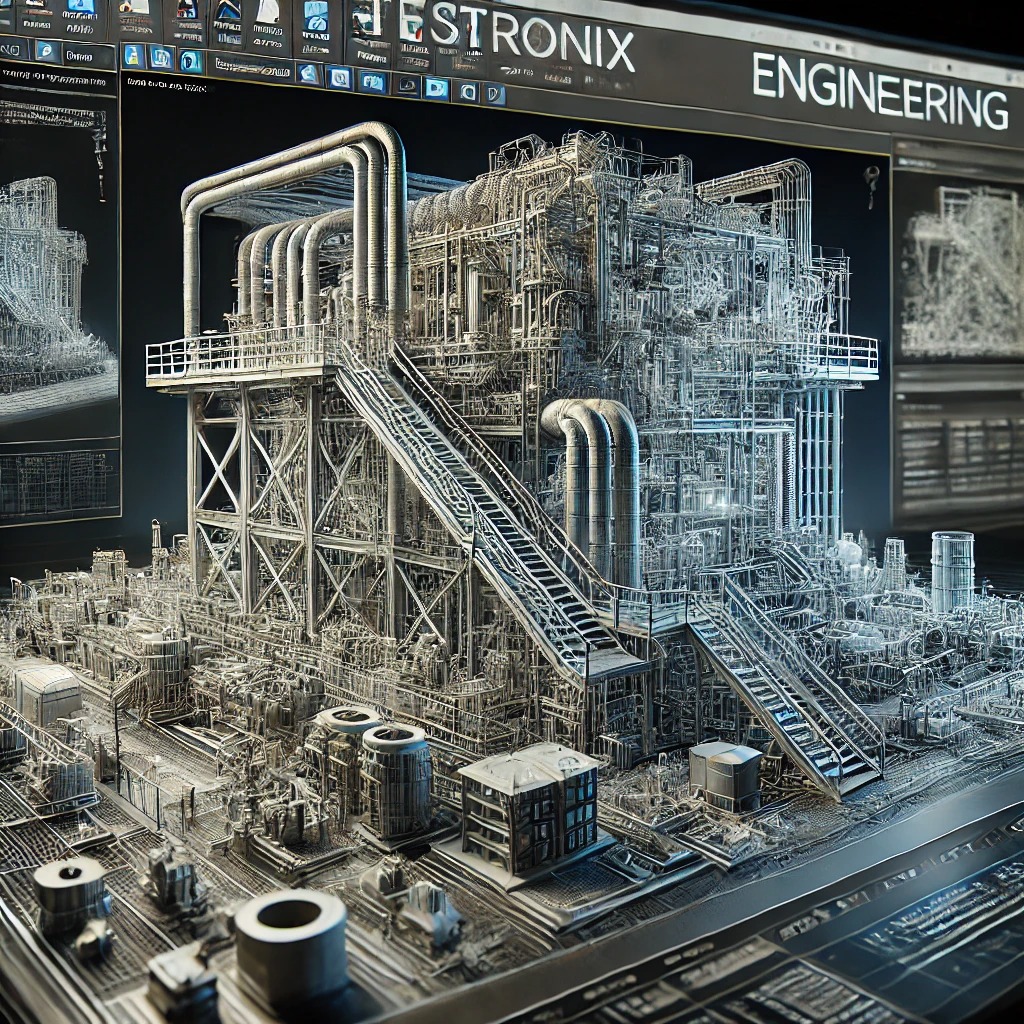

- Expertise in Modeling Complex Geometries : Our team specializes in creating models for highly intricate structures, from industrial pipe racks to layered frameworks. We use specialized tools that interpret complex geometries efficiently, ensuring that even the most layered and interconnected elements are accurately represented.

- Ensuring Software Compatibility : We recognize that our clients require models compatible with various platforms. Testronix works to ensure that each model integrates smoothly with vendor software, making collaboration easier and enabling seamless updates.

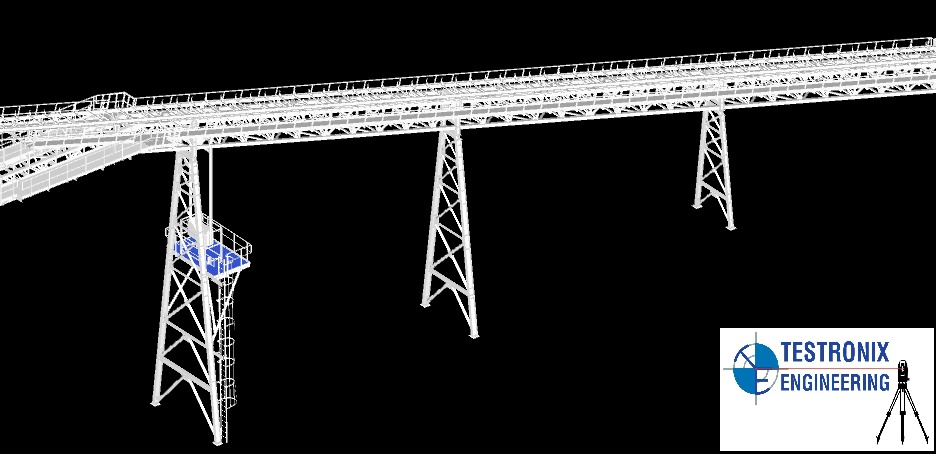

- Simplified, Usable Models : After developing a high-precision model, we work with vendors to simplify it for ease of use in their applications. Whether it’s for design, presentation, or engineering use, our final models provide a balance of detail and usability.

Case Studies: Bringing Complex Models to Life

Here’s a look at some of the challenging projects we’ve handled, showcasing how Testronix Engineering adds value for our clients:

- Oil & Gas Processing Facility : In this project, our team tackled an extensive network of interwoven pipelines, ducts, and structural elements in a large oil processing plant. Using high-resolution laser scanning, we captured complex geometries within tight deadlines. Post-processing and 3D modeling allowed the client to visualize and assess structural integrity, validate designs, and optimize maintenance schedules—all based on precise as-built models.

- Power Plant Structural Framework : In collaboration with a power plant, Testronix was tasked with creating a 3D model of a complex boiler structure and supporting framework. This project involved thousands of interconnected elements, each requiring accurate representation for safety audits and maintenance planning. Our team produced a detailed, scalable model, enabling stakeholders to make critical decisions based on reliable, data-driven insights.

- Industrial Machinery Assembly : A recent project required a highly detailed model of a manufacturing assembly with multiple layered components. Testronix modeled each element with precision, helping the client enhance design processes and improve layout planning. By providing a 3D model of the entire assembly, we empowered the client to optimize production workflows and reduce downtime for maintenance.

Addressing Pain Points in Converting Point Cloud Data to 3D Models

Each complex project comes with its unique data conversion challenges. These pain points are common in industrial 3D modeling:

- Data Volume Management: Large point cloud datasets can be difficult to process. At Testronix, we employ sophisticated data compression techniques that retain model integrity while making files manageable.

- Improving Model Readability: Excessive detail can overwhelm users, especially in intricate structures. We focus on striking the right balance, preserving essential elements while simplifying the model for practical use.

- Accurate Alignment and Stitching: For extensive sites, multiple scans need to be combined or "stitched" together accurately. Testronix’s expertise in alignment ensures seamless transitions, making the final model cohesive and reliable.

- Cost Efficiency: Processing large datasets can be time-intensive and costly. Testronix’s streamlined workflows and efficient processing reduce project timelines and optimize costs for our clients.

By addressing these pain points, we deliver precise, actionable models tailored to our clients' needs—whether for presentations, safety audits, or process optimizations.