Unleashing the Potential of Digital Twins Through Point Cloud Data

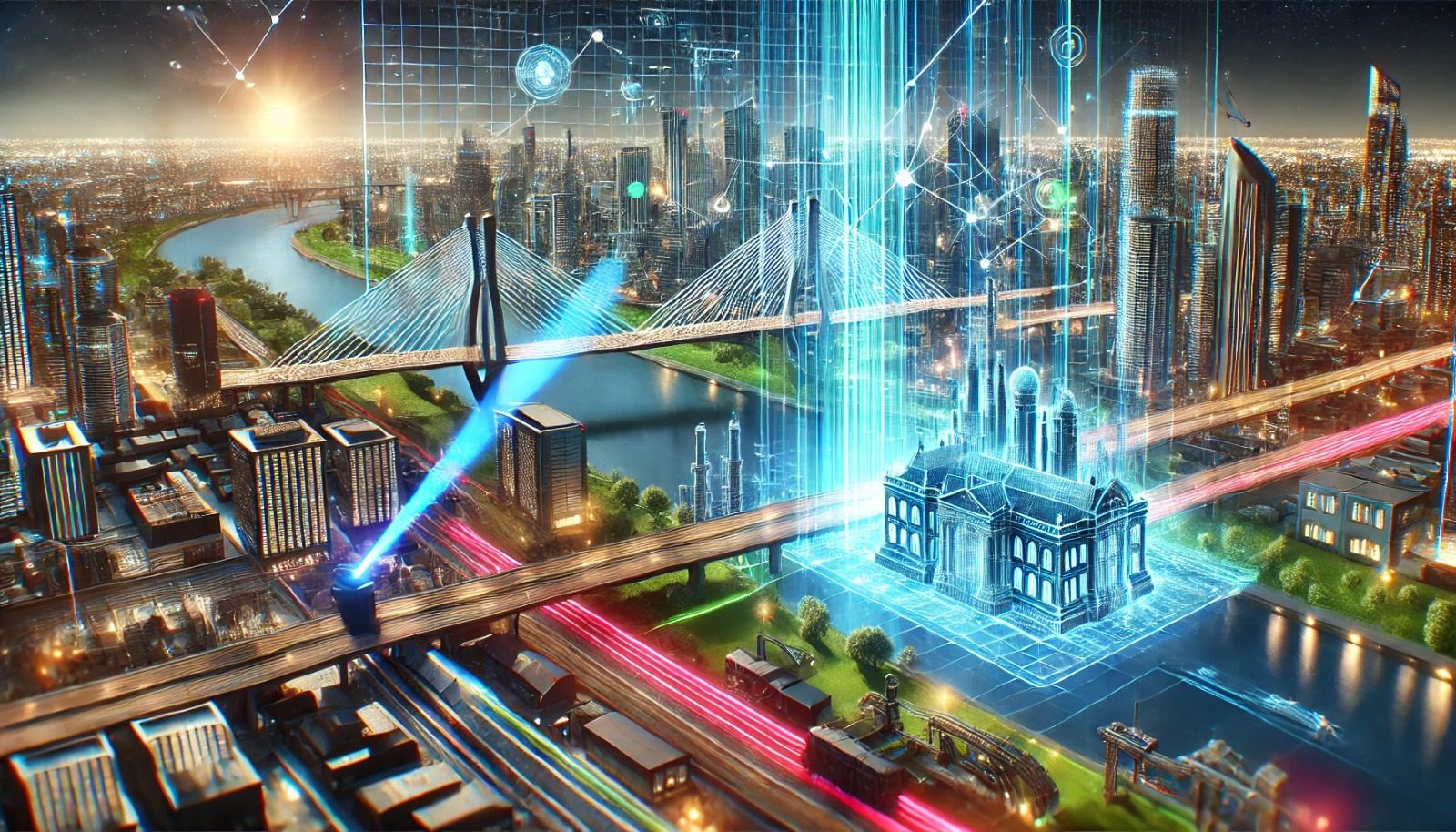

In the modern era of digital transformation, the concept of digital twins is revolutionizing industries by providing an unprecedented level of insight, control, and innovation. Digital twins, dynamic digital representations of physical assets, have become a cornerstone of next-generation technologies. A key enabler of this transformation is point cloud data, derived from laser scanning. This blog explores how point cloud data fuels digital twin technology, the critical role laser scanning plays, and how Testronix Engineering is at the forefront of delivering cutting-edge digital twin solutions.

What Are Digital Twins?

Digital twins are virtual replicas of physical systems, assets, or processes, enriched with real-time data to simulate, analyze, and predict performance. These dynamic models are crucial for industries such as manufacturing, construction, healthcare, and urban planning, as they provide actionable insights, improve operational efficiency, and enable better decision-making.

Digital twins are not static models. They integrate with IoT (Internet of Things) devices and advanced analytics to reflect the real-world condition of assets, creating a seamless interaction between the physical and virtual domains.

The Role of Point Cloud Data in Digital Twin Creation

Point cloud data serves as the foundation for creating highly accurate and detailed digital twins. Generated through laser scanning or LiDAR technology, point cloud data comprises millions of points that capture the spatial and geometric characteristics of a structure. This data is crucial for:

- Precision Modeling: Point clouds provide exact dimensions, enabling the creation of accurate 3D models for digital twins

- Complex Structures: For projects involving intricate or legacy structures, point cloud data captures minute details that would be challenging to measure manually

- Integration of Real-World Data: This data seamlessly integrates with Building Information Modeling (BIM) and other software tools to create comprehensive digital twins

How Laser Scanning Supports Next-Gen Technology

Laser scanning has emerged as the backbone of point cloud generation, providing speed, accuracy, and flexibility. Key advantages include:

- High-Speed Data Collection: Laser scanning rapidly captures 3D data of environments, reducing the time needed for surveys compared to manual methods.

- Unmatched Accuracy: It delivers highly detailed measurements with millimeter precision, ensuring digital twins accurately mirror real-world conditions

- Scalability: Laser scanning can accommodate projects of varying scales, from industrial plants to historic mansions

- Support for Advanced Analytics: Combined with AI and machine learning, laser-scanned data enables predictive analytics and simulation, driving innovations in maintenance, operations, and design

Testronix Engineering: Leading the Way in Digital Twin Solutions

Testronix Engineering has established itself as a leader in laser scanning and digital twin technology, offering solutions tailored to meet the unique needs of diverse industries. Here’s how Testronix is driving the future of digital twins:

Comprehensive Laser Scanning Services : Testronix employs state-of-the-art laser scanners to capture precise 3D point clouds. This data is used to create accurate digital twins for various applications, including construction, manufacturing, and infrastructure.

Enhanced Decision-Making : By converting point cloud data into actionable 3D models, Testronix provides clients with insights that improve planning, monitoring, and operational decision-making.

Customization and Flexibility : From as-built documentation to complex digital twins, Testronix tailors solutions to each client’s requirements, ensuring optimal results for specific projects.

Innovation and Research : Testronix stays at the forefront of innovation, exploring new methodologies such as integrating AI into point cloud processing to enhance the capabilities of digital twins

Real-World Applications of Digital Twins Powered by Laser Scanning

- Smart Cities : Digital twins of urban environments allow city planners to simulate and optimize traffic flows, utilities, and emergency responses.

- Industrial Plants : For large-scale industrial facilities, Testronix’s laser scanning services ensure that digital twins accurately reflect the complexities of pipelines, machinery, and layouts.

- Infrastructure Maintenance : Bridges and highways benefit from digital twins by enabling predictive maintenance and extending asset lifecycles

- Heritage Preservation : By creating digital replicas of historic structures, Testronix aids in preserving cultural heritage for future generations

Overcoming Challenges in Digital Twin Creation

Creating digital twins comes with challenges, such as handling vast amounts of point cloud data and ensuring interoperability across platforms. Testronix addresses these issues through:

- Efficient Data Processing: Advanced software tools streamline the conversion of raw point cloud data into usable models.

- Cross-Platform Integration: Ensuring that digital twins are compatible with a range of software ecosystems.

- Continuous Updates: Developing workflows for maintaining digital twins in sync with real-world changes

Conclusion: Shaping the Future with Testronix Engineering

The synergy between point cloud data and digital twin technology is transforming how we interact with the physical world. With laser scanning at its core, this technology is driving innovation across industries. Testronix Engineering stands as a pioneer, leveraging cutting-edge tools and methodologies to unlock the full potential of digital twins.

As we continue to explore the possibilities of this transformative technology, the collaboration between advanced tools and expert providers like Testronix ensures a future where digital twins become indispensable in shaping smarter, more efficient systems.