3D Laser scanning Company in INDIA.

In the age of digitization and advanced engineering, 3D modeling has become a cornerstone for planning, design, and management across various industries. However, a recurring challenge has surfaced: discrepancies between 3D models and the actual as-built reality. These mismatches can lead to inefficiencies, increased costs, and project delays. To address these issues, it is vital to understand the root causes, explore best practices, and leverage cutting-edge technologies like laser scanning. Here, we delve into why 3D models often fail to reflect reality accurately and how Testronix Engineering is addressing these challenges.

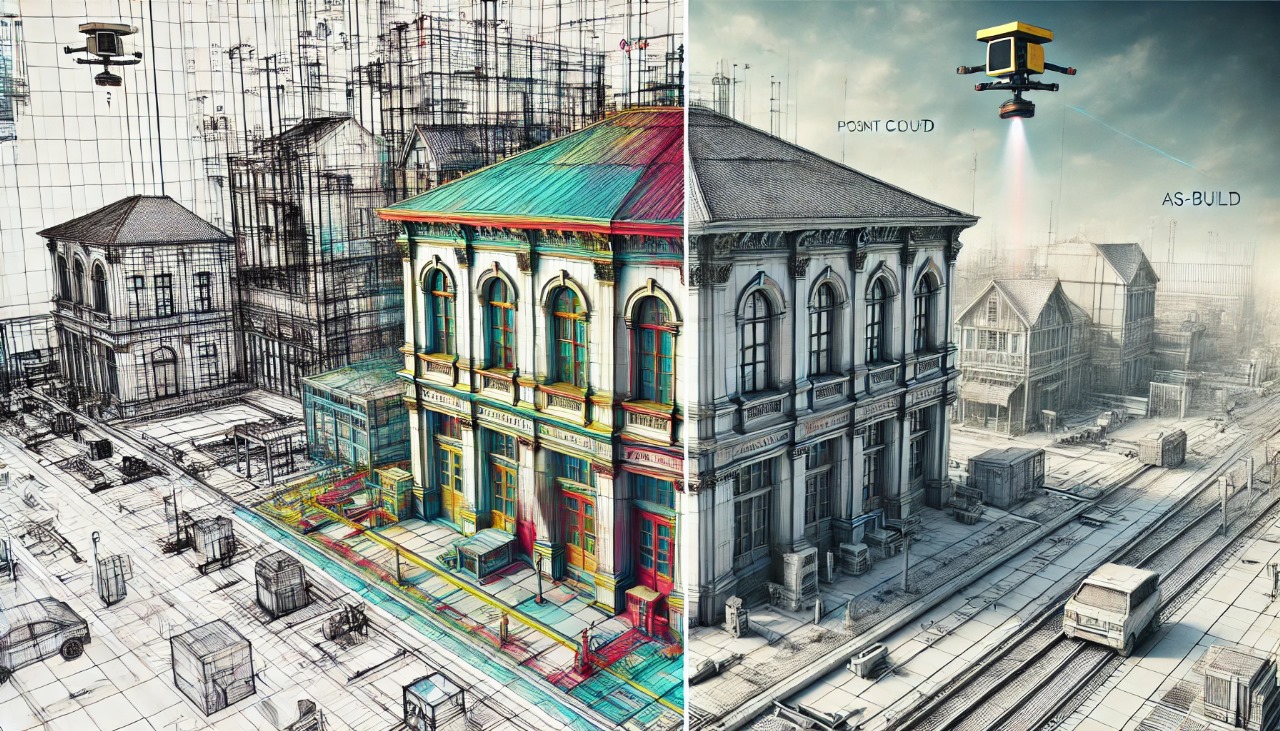

Laser scanning technology has revolutionized the process of capturing as-built conditions. By emitting laser beams to measure distances, these scanners create highly accurate point clouds that serve as the foundation for 3D modeling. Unlike traditional methods, laser scanning captures millions of data points in a fraction of the time, ensuring unmatched precision and completeness.

Testronix recently completed a large-scale scanning project for a petrochemical plant. The project involved capturing terabytes of point cloud data for detailed 3D modeling. Here’s how we managed the data effectively:

Testronix Engineering has emerged as a leader in the field of laser scanning and 3D modeling. With a focus on precision, efficiency, and client satisfaction, the company leverages state-of-the-art technology to address the challenges of as-built documentation.