3D Laser scanning Company in INDIA.

In industries like oil and gas, flare stacks play a critical role in safely burning off excess gases. However, ensuring their proper alignment and structural integrity is vital to avoid costly downtime and potential hazards. At Testronix Engineering, we leverage cutting-edge 3D laser scanning technology to revolutionize flare stack inspections, offering a precise, efficient, and non-invasive solution.

Traditional flare stack inspection methods are often labor-intensive, risky, and time-consuming.

Climbing the structure or using drones to visually inspect alignment and integrity can introduce human error and limited accuracy. For a leading petrochemical company, their aging flare stack was raising concerns about misalignment and potential structural wear, prompting the need for a more accurate and efficient assessment method.

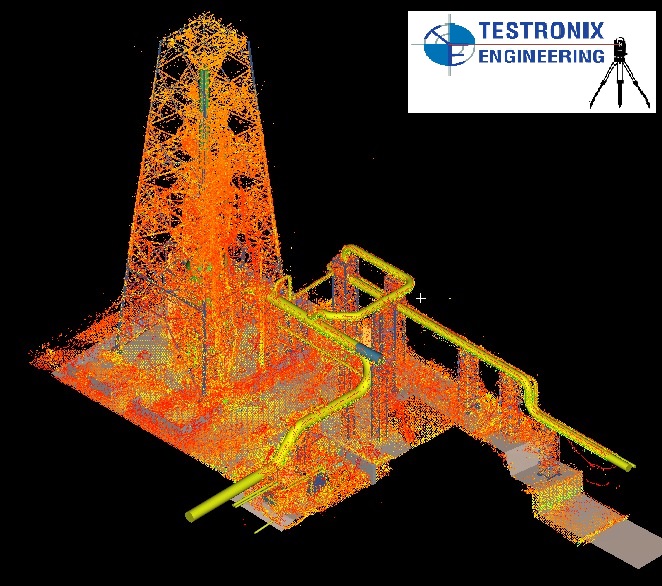

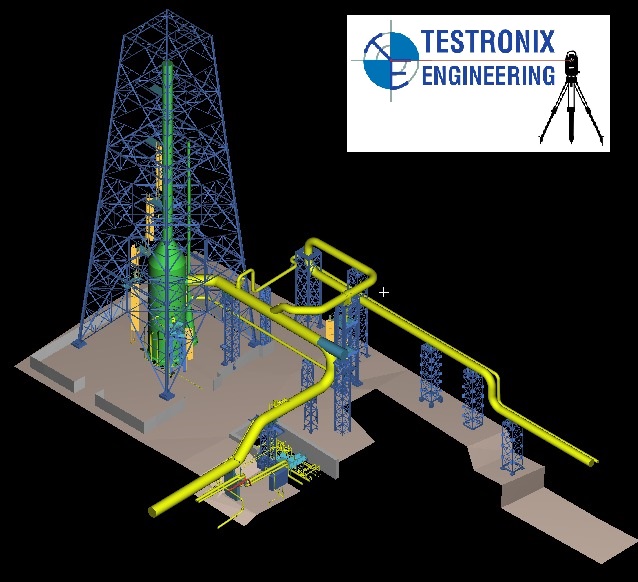

The Testronix Solution Using advanced 3D laser scanning technology, Testronix Engineering conducted a comprehensive inspection of the flare stack. Here’s how our process unfolded:

The Results The application of 3D laser scanning technology delivered remarkable outcomes:

Client Feedback “Testronix Engineering’s laser scanning technology exceeded our expectations. The precision and clarity of the inspection report provided us with the confidence to take immediate action and prevent potential hazards. Their expertise has set a new standard for flare stack inspections.” – Plant Manager, Petrochemical Company

Conclusion At Testronix Engineering, we are redefining how critical structures like flare stacks are inspected. By combining state-of-the-art 3D laser scanning technology with our industry expertise, we help clients ensure safety, optimize maintenance, and reduce operational disruptions.