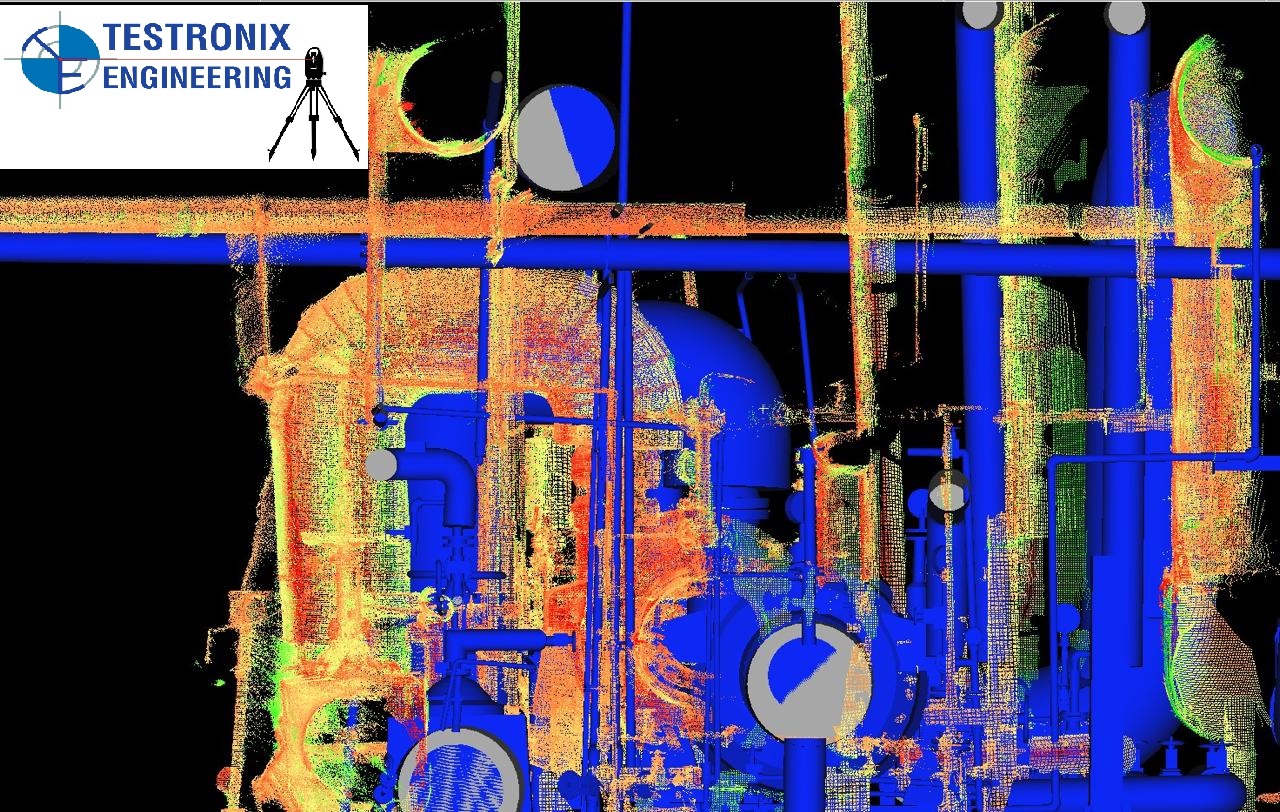

3D Laser scanning Company in INDIA.

In modern AEC industry, 3D laser scanning has become an indispensable tool for capturing precise as-built conditions. However, the accuracy of these scans depends on the careful processing of data, any missteps in this process can lead to significant project challenges.

When laser scan data is improperly stitched, it can result in misaligned or distorted 3D models. Such inaccuracies can cause design errors, leading to construction mistakes that causes costly rework. Studies have shown that rework can account for up to 12-15% of total project costs, but with accurate laser scanning, this can be reduced to as low as 1-3%.Therefore, ensuring precise data stitching is crucial to minimize errors and control project expenses.

How Testronix is Mastering Data Processing Challenges

Recognizing these challenges, Testronix Engineering has developed advanced solutions to address data processing issues in laser scanning.

By addressing the complexities of data stitching and processing, Testronix ensures that clients receive precise and reliable 3D models, thereby enhancing project efficiency and reducing the risk of costly errors.

Incorporating accurate laser scanning data is not just a technological advancement, it's a strategic imperative for successful project execution. With Testronix's expertise, stakeholders can confidently navigate the challenges of data processing, leading to improved outcomes and optimized resources.

Contact us to get accurate and reliable data sets for your projects [email protected]