3D Laser scanning Company in INDIA.

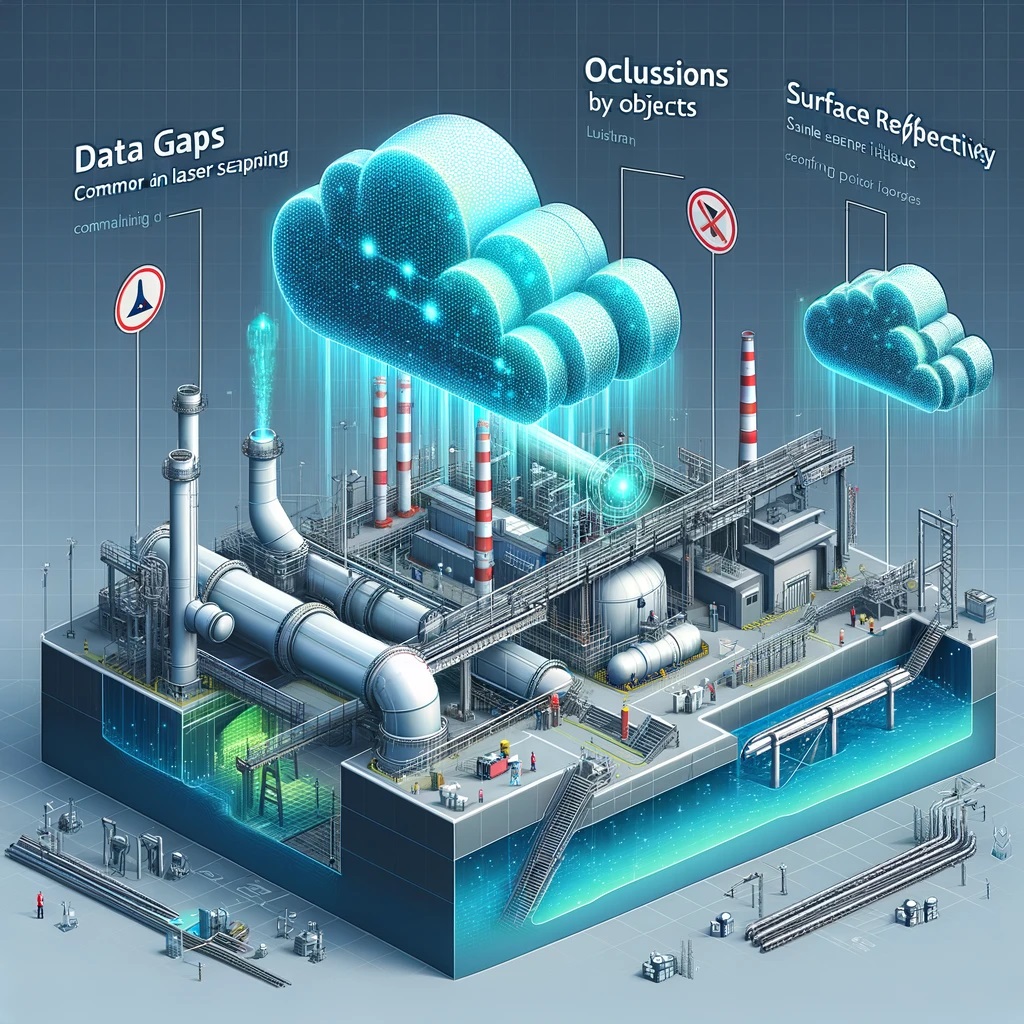

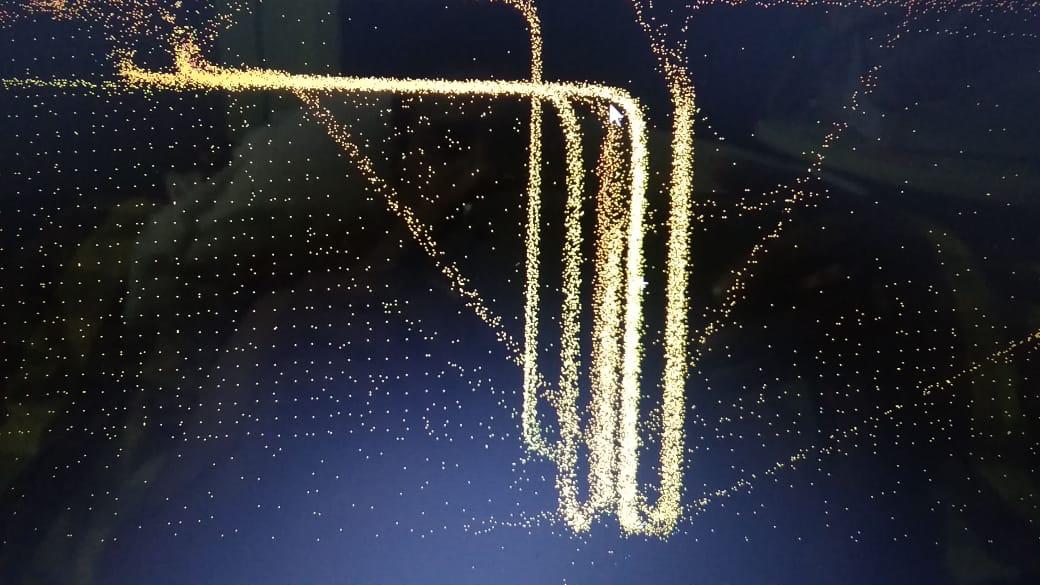

3D laser scanning has revolutionized industries like construction, manufacturing, oil and gas, and architecture by providing highly accurate data in less time. However, one recurring challenge in laser scanning is the occurrence of data gaps, which can compromise the accuracy of as-built models or 3D representations. These gaps can result from occlusions, environmental factors, or improper scanner settings. This blog will guide you on how to avoid these pitfalls, ensure consistent data capture, and how Testronix Engineering is excelling in mastering these techniques.

Data gaps are sections of the scanned area that lack sufficient detail or information. Some common causes include:

Here are some best practices to minimize data gaps and capture consistent, high-quality data:

At Testronix Engineering, we understand the challenges posed by data gaps and have developed strategies to overcome them. Here’s how we ensure flawless data capture:

Ready to Solve Your Laser Scanning Challenges?

If your projects are plagued by data gaps, let Testronix Engineering step in. We specialize in addressing challenges related to occlusions, surface issues, and complex environments. With our expertise and commitment, we can provide you with seamless, accurate data for your next project.